To build a cruise ship like Royal Caribbean's Utopia of the Seas or Star of the Seas, it's anything but a simple process.

Royal Caribbean's new cruise ships take years of research, design, and testing before actual construction can begin. It's an enormous engineering, research, and imagination feat before the first passengers are able to step onboard.

Royal Caribbean shared an inside look at the process, and it's a fascinating look at one of the most complex endeavors within the travel industry.

Step 1: It All Starts With an Idea

Royal Caribbean starts off designing a new ship with the conceptual stage, posing an important question: "Who are we building this for?".

According to the cruise line, their team begins by identifying which type of guests they want to attract. From there, they determine what those guests want, what they need, and how to exceed those expectations with something entirely new.

As Jason Liberty, Royal Caribbean Group CEO, put it, "It’s in our DNA to wake up every day dreaming and innovating about what the future experience could look like."

They call it "ideation" and it's a brainstorming of process of what's possible to do on a floating hotel at sea. Many of the venues and attractions we take for granted today on a Royal Caribbean ship were born of this process.

Ideas are tossed around conference rooms filled with designers, architects, engineers, and brand experts to determine what sounds fun, and how practical it actually is. The good ones make their way to a new ship.

Step 2: From Concept to Blueprint

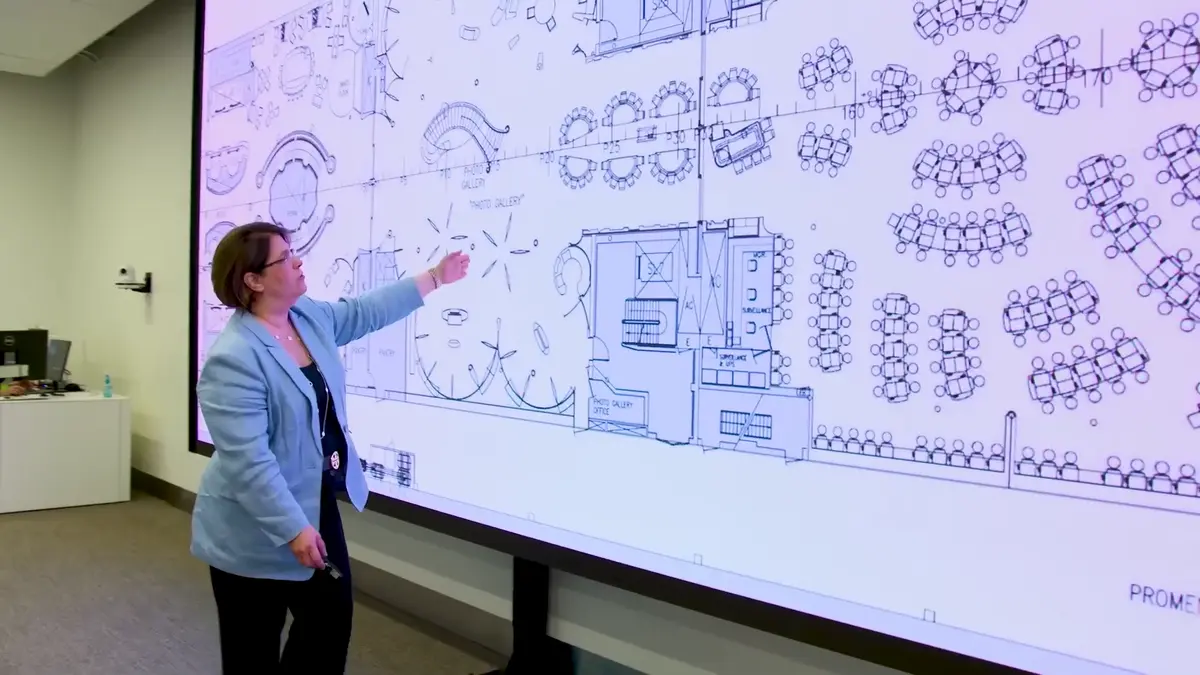

With the ideas in place, Royal Caribbean moves on to take those ideas and turn them into designs.

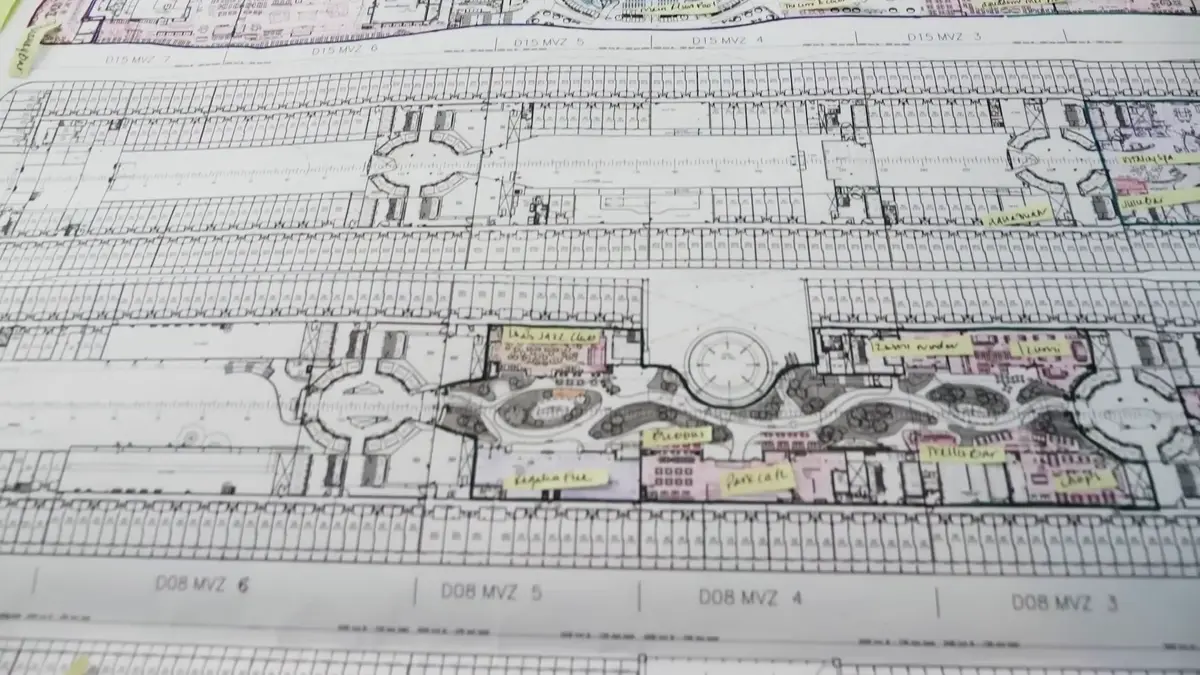

According to Royal Caribbean, the design phase for a ship like Utopia of the Seas took over 1.5 million working hours. These hours go into creating detailed blueprints, renderings, and workshop plans.

This step of the process can take a while, as the cruise line must account for every part of the ship. Every room, hallway, panel, and accessway must be planned out.

Only after this intensive work is complete can construction begin.

Step 3: Selecting the Shipyard and Starting Construction

With a plan in place, a cruise line has to find someone to actually build it.

There are a handful of shipyards around the world that are capable (and knowledgeable) to build cruise ships. Surprisingly, none of them are in the United States.

Royal Caribbean works with one of three major shipyards, depending on the size and class of the ship.

The first construction milestone is the steel-cutting ceremony. This is the symbolic beginning of construction when the first sheet of steel is cut.

From that steel, a ceremonial silhouette of the ship is cut—marking the start of a long and complex building process.

Step 4: Building the Ship Block by Block

Cruise ships are built differently from buildings on land.

On a basic level, cruise ships are assembled by putting together blocks of pre-built units to create the ship's super-structure.

Each block contains portions of the ship’s structure, including framing, electrical systems, and plumbing. These blocks are assembled off-site and then transported to the shipyard, where they are connected piece by piece.

The first block to go into place is the keel, which forms the backbone of the ship.

As part of maritime tradition, there is a keel-laying ceremony where a pair of lucky coins are placed under the keel as a symbol of good luck.

Step 5: Welding, Cabling, and Engineering

Once the keel is laid, the blocks are added in stages over the next 12 to 18 months. This phase is highly technical. It includes:

- Installing engines, propellers, stabilizers

- Running miles of cables for power and data

- Connecting AC ducts, plumbing, and exhaust systems

- Welding together structural steel and sealing seams

All of this work is happening while cabins are being built separately in nearby facilities.

These staterooms are fully fabricated off-site and then lifted into place using cranes. It takes about one year to complete the cabins and install them on board.

Step 6: Float Out

After all the major structural and mechanical systems are in place, the ship is ready for its float out.

At this point, the ship has a completed exterior with a bow, stern, and hull. The dry dock is slowly filled with water, and the ship floats for the first time. From this point forward, the ship will remain afloat.

Although the vessel now looks finished, there’s still a tremendous amount of work to complete.

Step 7: Sea Trials

Just like a new car, cruise ships must be tested to ensure their systems work and the vessel can handle sailing.

Sea trials are a series of tests that examine how the ship performs under real-world conditions.

When sea trials take place, hundreds of specialists run tests to help assess different technical areas of the ship, and there were more than 450 specialists who helped to run the four days tests on the ship’s technical areas during this round of sea trials.

The team evaluates:

- Speed and engine response

- Navigation systems and maneuverability

- Stabilizers and propulsion

- Emergency systems and alarms

- Compliance with performance guarantees

Sea trials allow certain navigation and technical systems to be tested that cannot be completed while the ship is docked. It's the final step of a ship's construction prior to being delivered to the cruise line and ensures that everything's in tip-top shape before officially joining the fleet.

Step 8: Interior Finish and Final Delivery

The finishing touches will take place right after the sea trials are complete, and this is when things passengers will need are added.

Examples of this includes:

- Installing signage, art, and furniture

- Stocking bars, kitchens, and retail stores

- Programming lights, AV systems, and software

- Deep cleaning and setup of public venues

Royal Caribbean also uses this time for what it calls "owner’s work", which are minor adjustments or enhancements the brand decides to implement before opening the ship to the public. This might involve additional decor, layout tweaks, or testing of new experiences.

Once complete, the ship is officially delivered.

This is when the ship is transferred to the cruise line, just like the keys to a new car being given to its owner.

Step 9: The First Guests Arrive

After years of planning and building, the ship is ready. Crews have trained, systems are tested, venues are polished, and the ship welcomes its first guests on board.

It's the culmination of all the work that took place to get the ship ready, from concepts to design to construction.

So, how long does it all take to complete?

Building a cruise ship takes five to seven years from initial concept to first sailing.

- Ideation & concept development: 1–2 years

- Engineering and detailed design: 1.5 years or more

- Construction and assembly: 3 years

- Float out: 1-2 days

- Sea trials: 3-11 days

- Final outfitting and pre-opening: Several weeks

That timeline means decisions made today will shape what guests experience half a decade from now.